Reasons for many pits in light-colored hard transparent PVC

欄目:Industry News 發(fā)布時間:2021-06-03 15:19

Sometimes we will find that after a few days after injection molding, white and other hard and transparent PVC parts will be found to have many small pits on the surface, which have to be scrapped, but the...

Sometimes we will find that after a few days after injection molding, white and other hard and transparent PVC parts will be found to have many small pits on the surface, which have to be scrapped, but the reason is related to our production line.

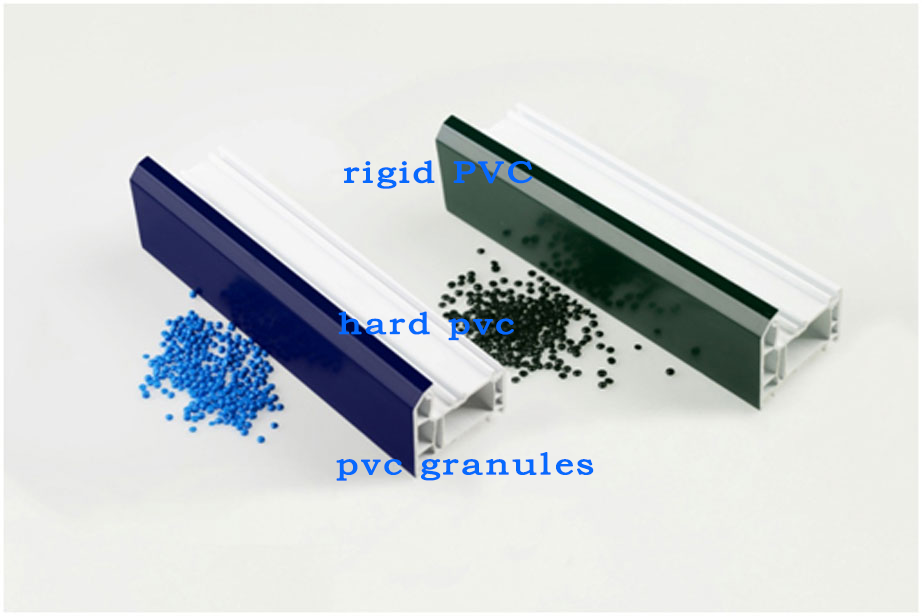

When producing dark-colored parts such as black or blue, a lot of colored dust will float in the air around the oven due to the hot air baking of the raw materials. If the hard transparent PVC parts are produced within the dusty range, the color dust will fall on the hard transparent PVC parts, but the dust cannot be seen with the naked eye at that time.

After a few days, the toner spreads, and the scope of contamination gradually increases, slowly turning into clearly visible blue or black pits, and the injection molded parts have to be shot.

Therefore, when producing white or hard transparent PVC parts, there can be no dark parts such as black or blue in the production, otherwise there will be endless troubles.